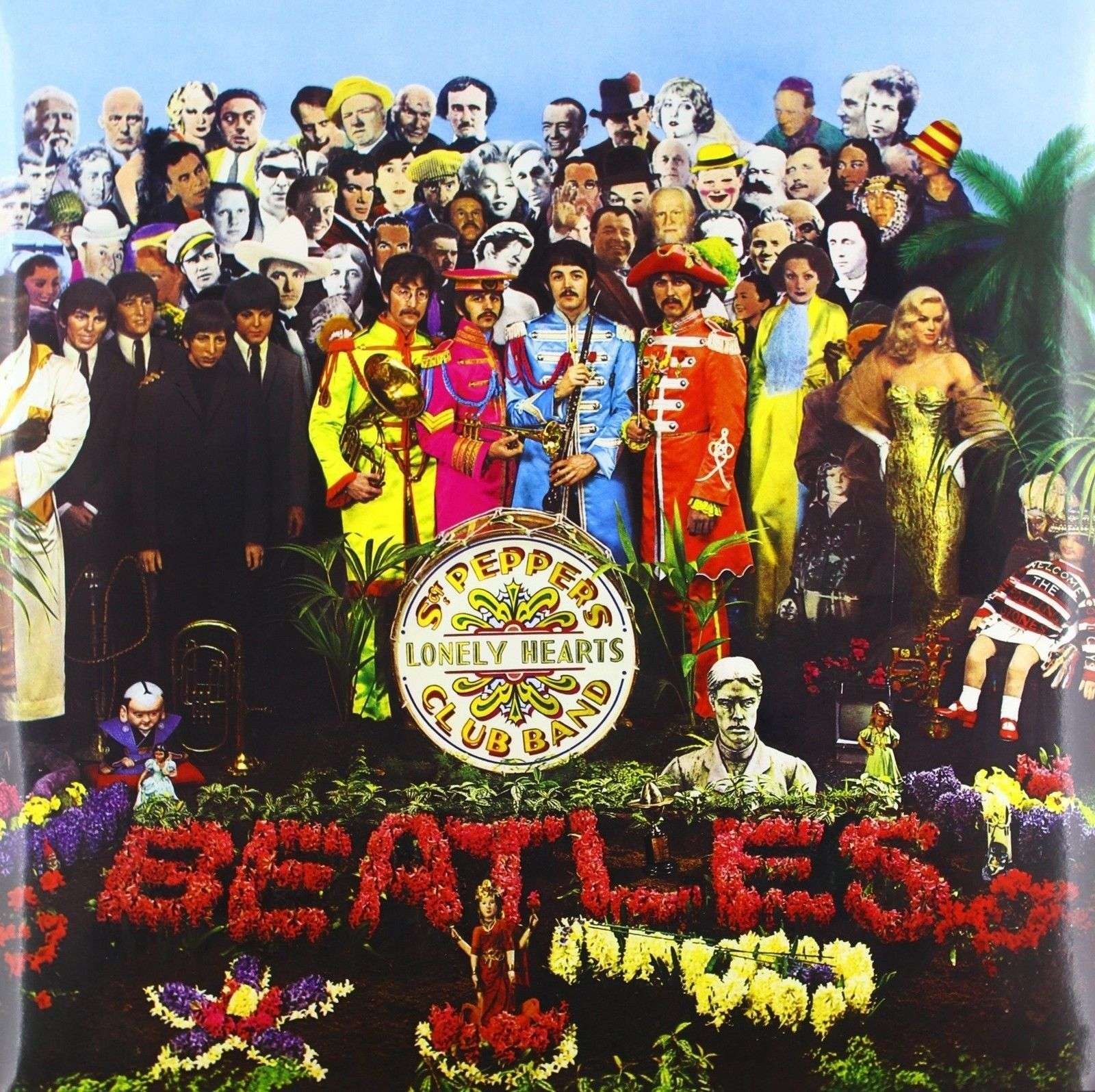

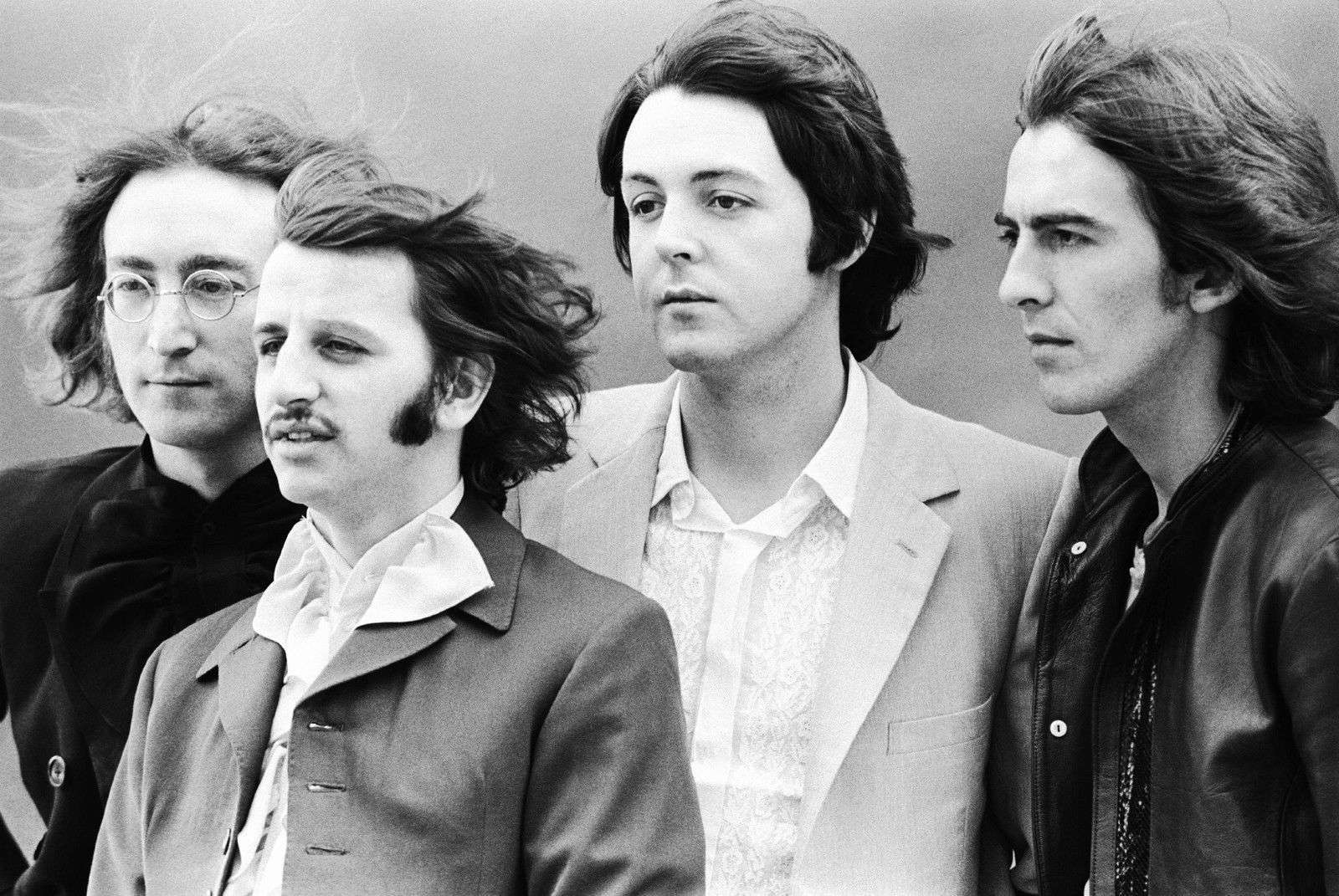

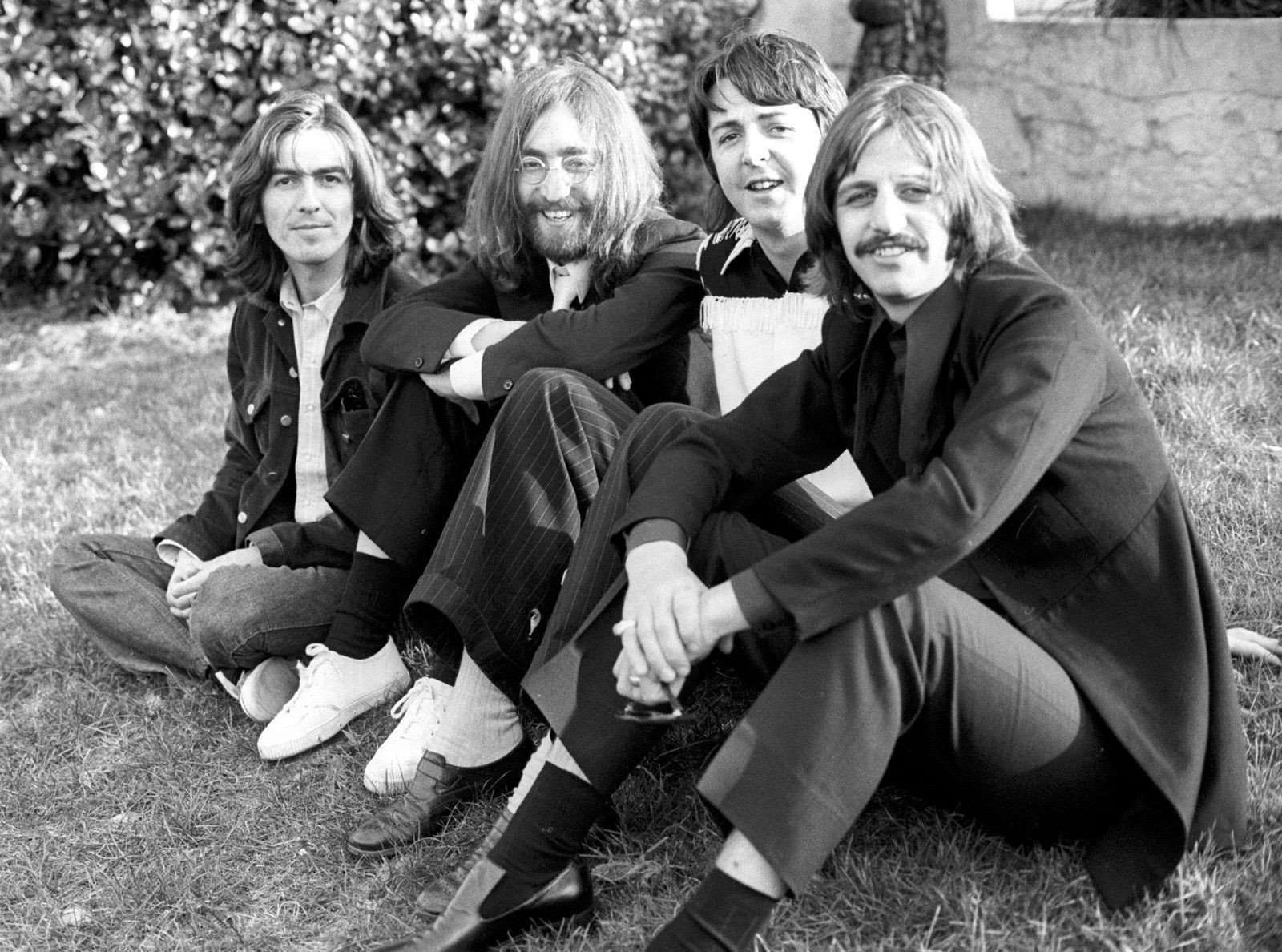

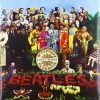

Sgt. Pepper’s Lonely Hearts Club Band

$28.90 Original price was: $28.90.$23.95Current price is: $23.95.

Sgt Two, first releasedindividually in 1988, featuring non-album A-sides and B-sides, EP tracks andrarities. With this release, The Beatles’ first four albums make their NorthAmerican stereo vinyl debuts Sgt. Pepper’s Lonely Hearts Club Band packaging includes replica psychedelicinner sleeve, cardboard cutout sheet and additional insert There has a

Sgt. Pepper’s Lonely Hearts Club Band

Product Details

- Vinyl (November 13, 2012)

- Number of Discs: 1

- Format: Original recording remastered

- Label: EMI

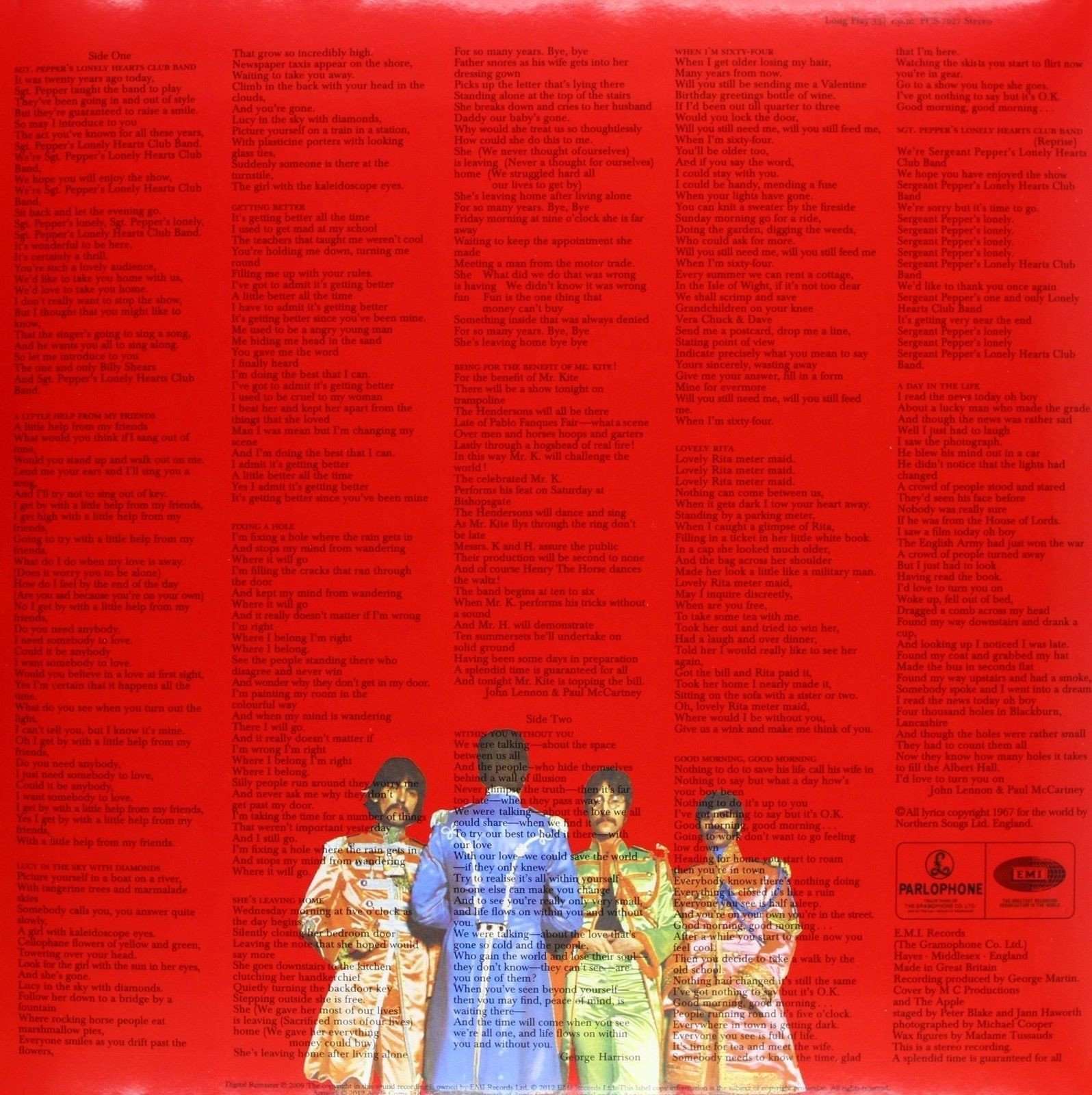

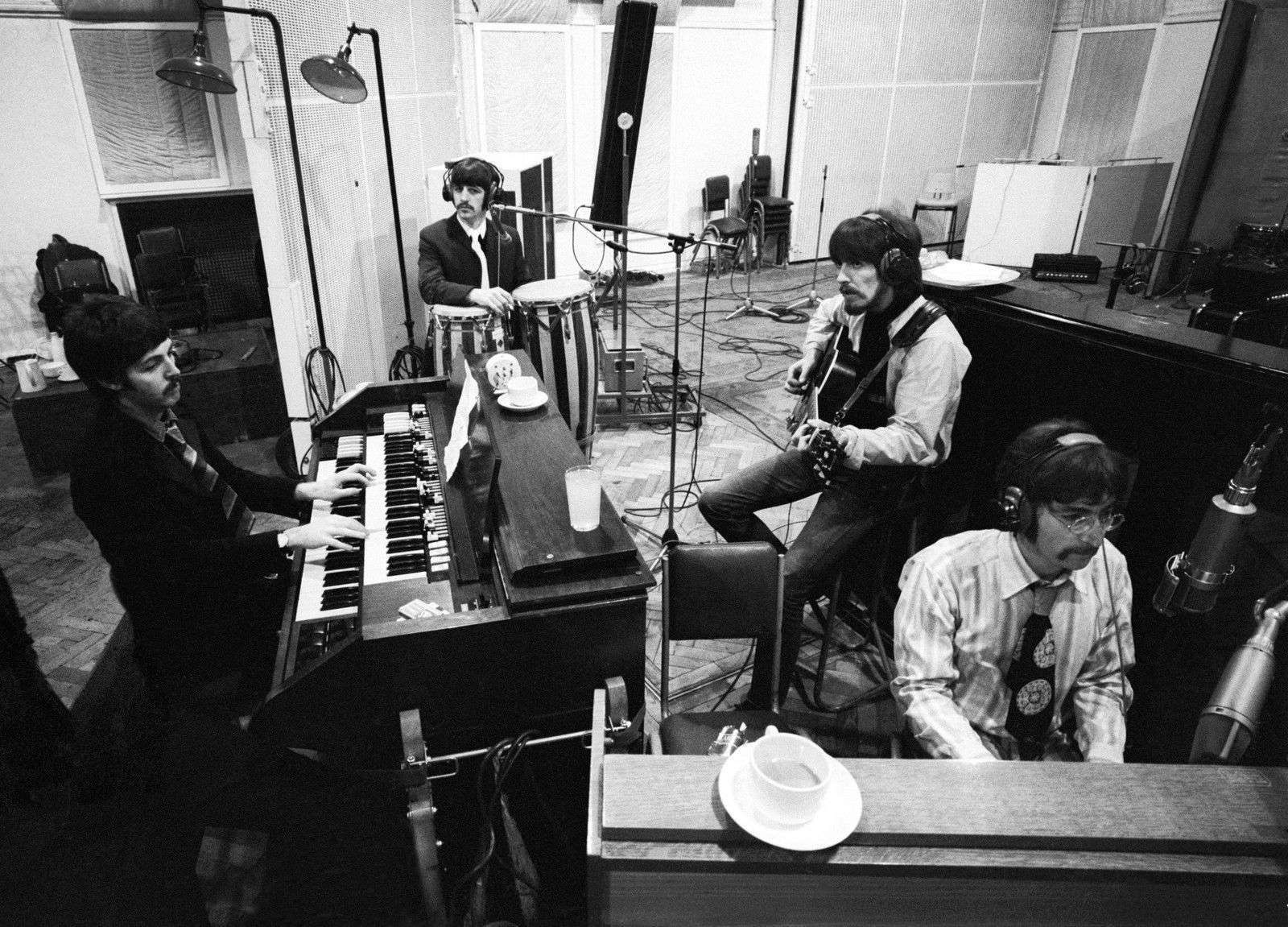

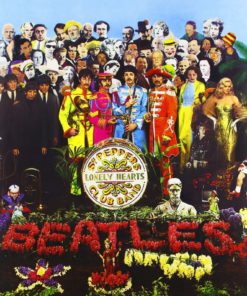

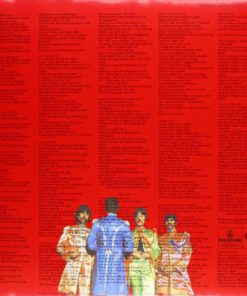

Editorial Reviews The Beatles’ acclaimed original studio album remasters, released on CD in2009, make their long-awaited stereo vinyl debut Manufactured on 180-gram, audiophile quality vinyl with replicated artwork,the 14 albums return to their original glory with details including the posterin The Beatles (The White Album), the Sgt. Pepper’s Lonely Heart Club Band’scut-outs, and special inner bags for some of the titles The titles include The Beatles’ 12 original UK albums, first released between1963 and 1970, the US-originated Magical Mystery Tour, now part of the group’score catalogue, and Past Masters, Volumes One & Two, first releasedindividually in 1988, featuring non-album A-sides and B-sides, EP tracks andrarities. With this release, The Beatles’ first four albums make their NorthAmerican stereo vinyl debuts Sgt. Pepper’s Lonely Hearts Club Band packaging includes replica psychedelicinner sleeve, cardboard cutout sheet and additional insert There has always been demand for The Beatles’ albums on vinyl. Indeed, 2011’sbest-selling vinyl LP in the United States was Abbey Road. Following thesuccess of The Beatles’ acclaimed, GRAMMY Award-winning 2009 CD remasters, itwas decided that the sound experts at EMI’s Abbey Road Studios should createnew versions of The Beatles’ vinyl LPs. The project demanded the samemeticulous approach taken for the CD releases, and the brief was a simple one:cut the digital remasters to vinyl with an absolute minimum of compromise tothe sound. However, the process involved to do that was far from simple The first stage in transferring the sound of a master recording to vinyl isthe creation of a disc to be used during vinyl manufacture. There were twooptions to consider. A Direct Metal Master (DMM), developed in the lateseventies, allows sound to be cut directly into a stainless steel disc coatedwith a hard copper alloy. The older, alternative method is to cut the soundinto the soft lacquer coating on a nickel disc – the first of several stepsleading to the production of a stamper to press the vinyl A ‘blind’ listening test was arranged to choose between a ‘lacquer’ or’copper’ cut. Using both methods, A Hard Day’s Night was pressed with tenseconds of silence at the beginning and end of each side. This allowed notonly the reproduction of the music to be assessed, but also the noise made bythe vinyl itself. After much discussion, two factors swung the decisiontowards using the lacquer process. First, it was judged to create a warmersound than a DMM. Secondly, there was a practical advantage of having ‘blank’discs of a consistent quality when cutting lacquers The next step was to use the Neumann VMS80 cutting lathe at Abbey Road.Following thorough mechanical and electrical tests to ensure it was operatingin peak condition, engineer Sean Magee cut the LPs in chronological releaseorder. He used the original 24-bit remasters rather than the 16-bit versionsthat were required for CD production. It was also decided to use the remastersthat had not undergone ‘limiting’ – a procedure to increase the sound level,which is deemed necessary for most current pop CDs Having made initial test cuts, Magee pinpointed any sound problems that canoccur during playback of vinyl records. To rectify them, changes were made tothe remasters with a Digital Audio Workstation. For example, each vinyl albumwas listened to for any ‘sibilant episodes’ – vocal distortion that can occuron consonant sounds such as S and T. These were corrected by reducing thelevel in the very small portion of sound causing the undesired effect.Similarly, any likelihood of ‘inner-groove distortion’ was addressed. As thestylus approaches the centre of the record, it is liable to track the grooveless accurately. This can affect the high-middle frequencies, producing a’mushy’ sound particularly noticeable on vocals. Using what Magee hasdescribed as ‘surgical EQ,’ problem frequencies were identified and reduced inlevel to compensate for this The last phase of the vinyl mastering process began with the arrival of thefirst batches of test pressings made from master lacquers that had been sentto the two pressing plant factories. Stringent quality tests identified anynoise or click appearing on more than one test pressing in the same place. Ifthis happened, it was clear that the undesired sounds had been introducedeither during the cutting or the pressing stage and so the test records wererejected. In the quest to achieve the highest quality possible, the Abbey Roadteam worked closely with the pressing factories and the manufacturers of thelacquer and cutting styli An additional and unusual challenge was to ensure the proper playback of thesounds embedded in the ‘lock-groove’ at the end of side two of Sgt. Pepper’sLonely Hearts Club Band. Requiring a combination of good timing and luck, ithad always been a lengthy and costly process to make it work properly. Infact, it was so tricky, it had never been attempted for American pressings ofthe LP. Naturally, Sean Magee and the team perfected this and the garbledmessage is heard as originally intended on the remastered Sgt. Pepper LP.

- Canada shipment can take up to 10 days

- Alaska, Hawaii, and Puerto Rico shipment can take up to 10 days, and some items may not be permitted to ship to these locations.

- If any shipment is not permitted to your area, full refund will be issued within two business days.

- Refund given as money back (no exchanges)

- Return Shipping to be paid by buyer, unless item defective or damaged.

- 15% Restocking fee applies unless return due to defective or damaged product.

- Perishable or Hazardous Goods are not returnable. Returns may require compliance with Manufacturer policies.

Related products