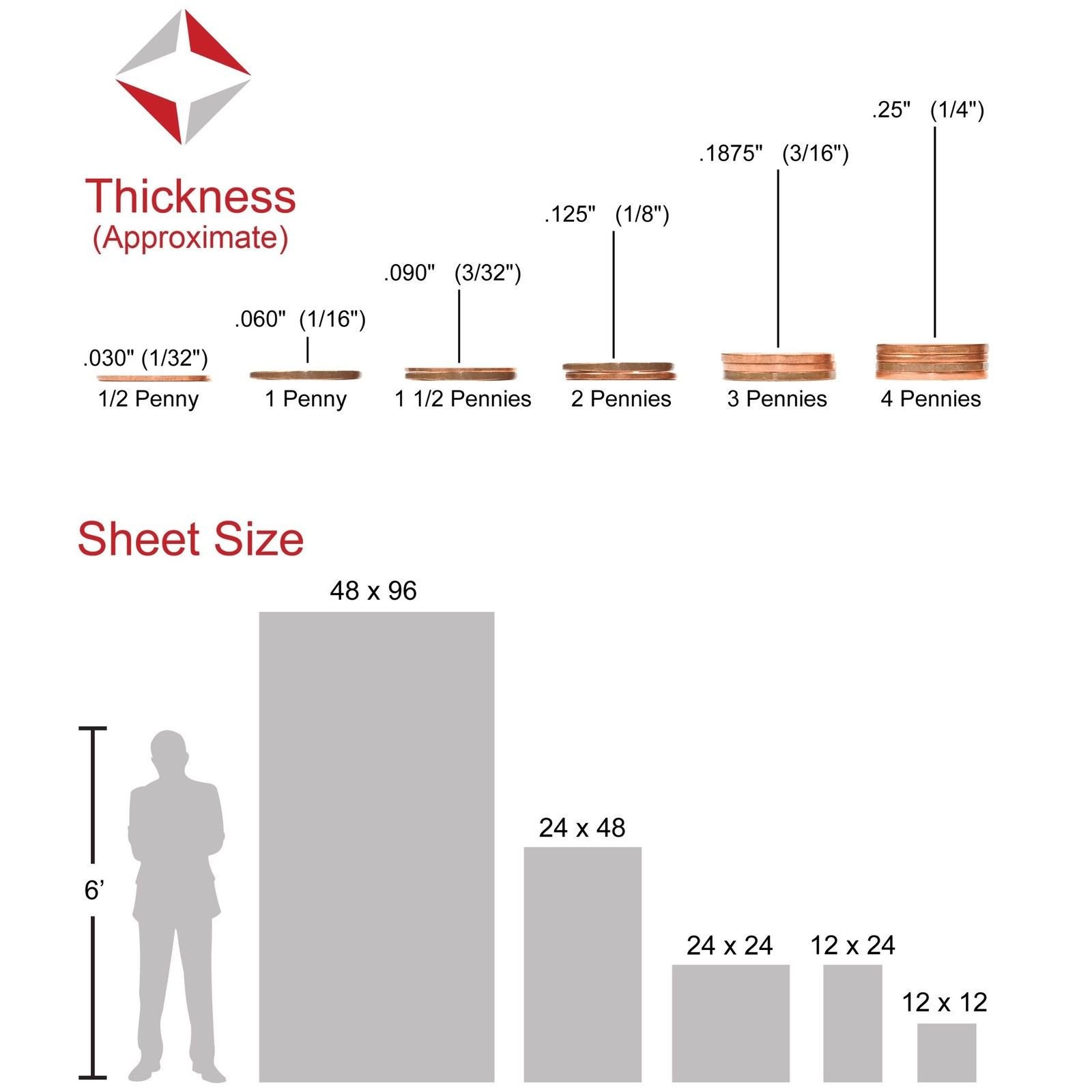

Kydex V – Black 12″ X 12″ X 0.125″ Pack Of 1 Sheet

$18.90 Original price was: $18.90.$12.95Current price is: $12.95.

KYDEX® V – Black 12″ x 12″ x 0 1 3.20mm (0.125″) – Ideally the core sheet temperatureshould be within 10°F of the surface temperature. Sheet Appearance DuringHeating As KYDEX® V sheet is heated, the inherent stresses in the sheet willrelax. Stage I: The heating is marked by wide undulations and softening. Stage II: The material will start to f

Product Details

-

- Item Weight: 12.8 ounces

- Shipping Weight: 13.6 ounces

KYDEX® V KYDEX® V sheet has excellent forming properties, which results inuniform wall thicknesses and crisp detail. KYDEX® V sheet forms to deep drawswith low forces when heated to the upper end of the forming temperature range.Unlike many other thermoforming sheets, KYDEX® V sheet has unusually highresistance to hot tearing. Forming Guidelines – Oven temperatures should beset differently than the settings used for ABS or FR-ABS. – Typical heatersettings (percentage timers) are 30% – 50% top heaters and 50% – 70% bottomheaters. – The most frequent problem is trying to heat the sheet too quickly,particularly on the primary surface. – Cycle times will vary depending on theoven conditions and grade of KYDEX® V sheet being formed. – When formingKYDEX® V sheet, it is better to rely on the sheet appearance during heatingthan on fixed cycle times. – Forming temperatures – Guidelines: (Sheet shouldnot exceed 204°C (400°F). 165 – 177°C (330 – 350°F) for < 1.50mm (0.060″). 182- 196°C (360 – 385°F) for 1.50mm to 3.20mm (0.060″ to 0.125″). 196 – 204°C(385 – 400°F) for > 3.20mm (0.125″) – Ideally the core sheet temperatureshould be within 10°F of the surface temperature. Sheet Appearance DuringHeating As KYDEX® V sheet is heated, the inherent stresses in the sheet willrelax. Stage I: The heating is marked by wide undulations and softening. Stage II: The material will start to form small ripples (known as oilcanning). . Stage III: The material will start to smooth out and sag (KYDEX®V sheet will generally sag less than other thermoplastics due to its high meltstrength. . Stage IV: The ripples will have smoothed out indicating thatmost stresses have been removed. 10 to 30 seconds afterwards the sheet isready to form.

- Canada shipment can take up to 10 days

- Alaska, Hawaii, and Puerto Rico shipment can take up to 10 days, and some items may not be permitted to ship to these locations.

- If any shipment is not permitted to your area, full refund will be issued within two business days.

- Refund given as money back (no exchanges)

- Return Shipping to be paid by buyer, unless item defective or damaged.

- 15% Restocking fee applies unless return due to defective or damaged product.

- Perishable or Hazardous Goods are not returnable. Returns may require compliance with Manufacturer policies.

Related products