-

×

1 × $50.95

1 × $50.95 -

×

Capcom Fighting Tribute

1 × $48.95

Capcom Fighting Tribute

1 × $48.95 -

×

Camco 44561 Olympian Aluminum Stack Jacks, Stabilize and Level Your RV Or Camper - 2 Pack

1 × $26.95

Camco 44561 Olympian Aluminum Stack Jacks, Stabilize and Level Your RV Or Camper - 2 Pack

1 × $26.95 -

×

Treestand Buddy Starter Pack

1 × $154.95

Treestand Buddy Starter Pack

1 × $154.95 -

×

ICD-10-CM 2016: The Complete Official Draft Code Set (ICD-10-CM the Complete Official Codebook)

1 × $82.95

ICD-10-CM 2016: The Complete Official Draft Code Set (ICD-10-CM the Complete Official Codebook)

1 × $82.95 -

×

2 Pcs T10 Led Bulb Super Bright 1000Lm 6000K Led Canbus Error Free 912 921 T10 T15 AK-4014 Led Bulbs for For Chevrolet Ford GMC Honda Nissan Toyota Truck Backup Reverse Lights 45 Pcs Chipsets 45-SMD Led Light

1 × $12.95

2 Pcs T10 Led Bulb Super Bright 1000Lm 6000K Led Canbus Error Free 912 921 T10 T15 AK-4014 Led Bulbs for For Chevrolet Ford GMC Honda Nissan Toyota Truck Backup Reverse Lights 45 Pcs Chipsets 45-SMD Led Light

1 × $12.95 -

×

The Kids' Yoga Deck: 50 Poses and Games

1 × $20.95

The Kids' Yoga Deck: 50 Poses and Games

1 × $20.95 -

×

Stainless Works SSS010 Stainless Steel Beverage Dispenser Spigot (Fits 5/8 inch opening)

1 × $18.95

Stainless Works SSS010 Stainless Steel Beverage Dispenser Spigot (Fits 5/8 inch opening)

1 × $18.95 -

×

SZCO Supplies Viking Sword

1 × $48.95

SZCO Supplies Viking Sword

1 × $48.95 -

×

Wrapper - Hempwick Dispenser (colors may vary)

1 × $13.95

Wrapper - Hempwick Dispenser (colors may vary)

1 × $13.95 -

×

3M AquaPure AP431 Scale Inhibition Replacement Cartridge, Easy Change High Capacity Water Filter for AP430SS Replacement Water Filter

1 × $33.95

3M AquaPure AP431 Scale Inhibition Replacement Cartridge, Easy Change High Capacity Water Filter for AP430SS Replacement Water Filter

1 × $33.95 -

×

Star Shower Collection by BulbHead (Star Shower Tree Dazzler)

1 × $64.95

Star Shower Collection by BulbHead (Star Shower Tree Dazzler)

1 × $64.95 -

×

8 Tier Cascade Wedding Cake Stand (STYLE R800)

1 × $98.50

8 Tier Cascade Wedding Cake Stand (STYLE R800)

1 × $98.50 -

×

Ultra Pro Heavy Metal D20 2-Dice Set - Antique Bronze

1 × $17.95

Ultra Pro Heavy Metal D20 2-Dice Set - Antique Bronze

1 × $17.95 -

×

Eleven Madison Park: The Cookbook

1 × $52.95

Eleven Madison Park: The Cookbook

1 × $52.95 -

×

Cold Steel 92BKGMZ Gladius Trainer

1 × $38.95

Cold Steel 92BKGMZ Gladius Trainer

1 × $38.95 -

×

Finding Dory 10" Hank Plush

1 × $30.95

Finding Dory 10" Hank Plush

1 × $30.95

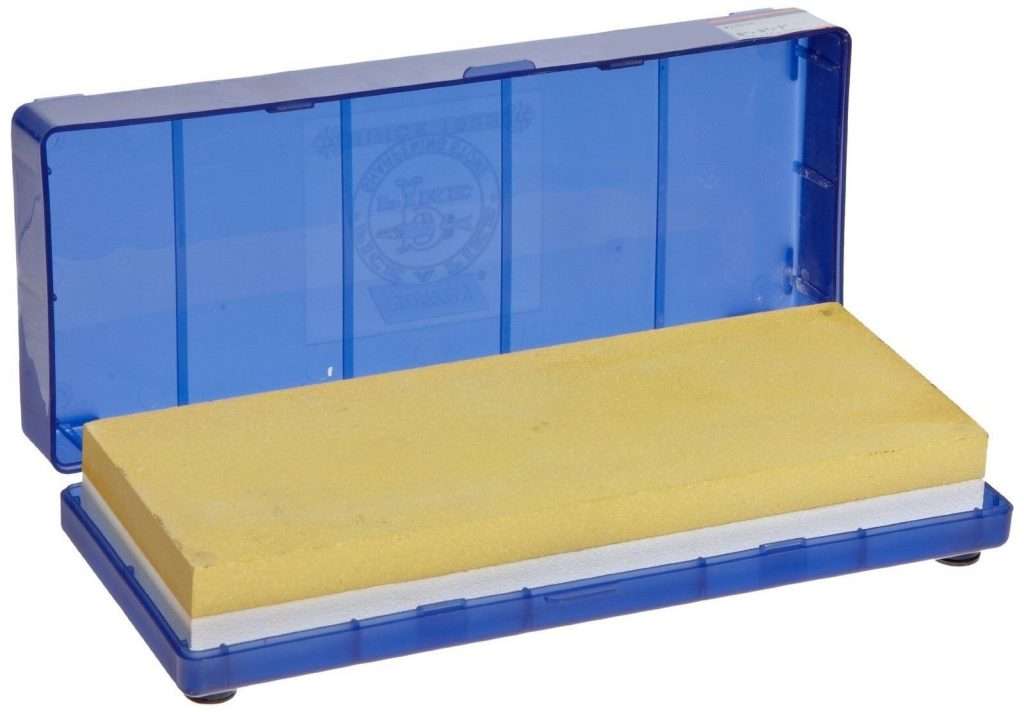

Norton 24336 Japanese-Style Combination Waterstone 4000/8000 Grit 8-Inch By 3..

$114.50 Original price was: $114.50.$89.95Current price is: $89.95.

Norton 24336 Japanese-Style Combination Waterstone 4000/8000 Grit, 8-Inch by 3-Inch by 1-Inch Product Details Product Dimensions: 8 1 this 1 x 8 x 3 inch (H x W x D)stone, suitable for bench use, cleans up easily with water, and comes encasedin a blue plastic hinged box W is width, the horizontal distance from left to right; D isdepth, the horizon

Norton 24336 Japanese-Style Combination Waterstone 4000/8000 Grit, 8-Inch by 3-Inch by 1-Inch

Product Details

-

- Product Dimensions: 8.5 x 3.2 x 1.2 inches ; 1.8 pounds

- Shipping Weight: 1.9 pounds

- Domestic Shipping: Item can be shipped within U.S.

- California residents: Click here for Proposition 65 warning.

- Item model number: 61463624336

The Norton 24336 Japanese-style 4000/8000-grit combinationwaterstone creates an abrasive slurry for effective sharpening, with 4000 griton one face for maintaining and refining a cutting edge, and 8000 grit on theopposite face for polishing cutting edges; this 1 x 8 x 3 inch (H x W x D)stone, suitable for bench use, cleans up easily with water, and comes encasedin a blue plastic hinged box. (H is height, the vertical distance from lowestto highest point; W is width, the horizontal distance from left to right; D isdepth, the horizontal distance from front to back.) The box protects thewaterstone and provides a reservoir to keep it moist. The removable box lid,with no-slip rubber feet, acts as a sharpening station to hold the waterstonein place during bench use. This synthetic waterstone is created by gradingabrasive material to a consistent particle size and blending it with bondingagents. It is then molded and surface-finished. Waterstones have a finer gritand softer bond than oilstones, and use water as the lubricant to develop aslurry, a thin paste of abrasive grains and water that removes metal with lesspressure than an oilstone requires. Cleanup is easier than with oil aslubricant. The use of waterstones originated in Japan, where such stones occurnaturally. As a result, some synthetic waterstones may be called Japanese-style. However, whether natural or synthetic, and whether labeled Japanese-style, all waterstones have the same basic characteristics. This stoneconforms to the Japanese Industrial Standard (JIS) for waterstones. Sharpeningstones, or whetstones, are abrasive surfaces used to sharpen and hone theedges of steel cutting implements such as chisels, knives, scissors, handscrapers, and plane blades. Sharpening is the process of creating or re-establishing a cutting edge by grinding away portions of the metal to adjustthe angle of the edge and reform the shape. Honing removes smallimperfections. Stones can be flat, for working flat edges, or shaped, foredges that are more complex. Sharpening stones are made of natural orsynthetic materials that range from softer to harder, and are categorized bythe size of their abrasive particles, known as grit. A stone with a coarsergrit is used when more metal needs to be removed (e.g., when sharpening anicked or very dull blade); the stone with the finest grit produces thesharpest edge. Where numbers are assigned to specify grit, they range fromcoarser grit (low) to finer grit (high). Some sharpening stones are designedfor use with a lubricating liquid, some can be used dry, and others can beused either wet or dry. When used with lubricating liquid, a sharpening stonecan be called a waterstone or an oilstone, based on the lubricant required.Norton Abrasives manufactures sanding, grinding, and polishing abrasives, andhas been located in the United States since 1885. Norton, now a brand ofSaint-Gobain, meets ISO 9000 and 14001 certification for quality andenvironmental management standards. From the Manufacturer Waterstones aresynthetic stones designed to be softer than oil stones. These softer gradestones are used with water as the lubricant (versus oil) to develop fast-cutting slurry. Designed in a carefully planned and efficient sharpeningsequence. You get the level of abrasiveness that you need at each stage,without wasting time trying to sharpen your knives on a grit that is too fine,too soon.

PAYMENT POLICY

SHIPPING POLICY

Most items are shipped within one business day via UPS within the Continental United States.

- Canada shipment can take up to 10 days

- Alaska, Hawaii, and Puerto Rico shipment can take up to 10 days, and some items may not be permitted to ship to these locations.

- If any shipment is not permitted to your area, full refund will be issued within two business days.

RETURNS POLICY

All returns accepted within 30 days after receiving the item.

- Refund given as money back (no exchanges)

- Return Shipping to be paid by buyer, unless item defective or damaged.

- 15% Restocking fee applies unless return due to defective or damaged product.

- Perishable or Hazardous Goods are not returnable. Returns may require compliance with Manufacturer policies.

FEEDBACK

We take our reputation seriously. We buy and sell online, so we understand the value of trust. If you are unsatisfied with your order for any reason, please Contact Us and we will work with you to resolve it to your satisfaction.

Related products

-21%

-17%

-29%

-27%

-30%

-17%

-39%

-21%

Capcom Fighting Tribute

Capcom Fighting Tribute  Camco 44561 Olympian Aluminum Stack Jacks, Stabilize and Level Your RV Or Camper - 2 Pack

Camco 44561 Olympian Aluminum Stack Jacks, Stabilize and Level Your RV Or Camper - 2 Pack  Treestand Buddy Starter Pack

Treestand Buddy Starter Pack  ICD-10-CM 2016: The Complete Official Draft Code Set (ICD-10-CM the Complete Official Codebook)

ICD-10-CM 2016: The Complete Official Draft Code Set (ICD-10-CM the Complete Official Codebook)  2 Pcs T10 Led Bulb Super Bright 1000Lm 6000K Led Canbus Error Free 912 921 T10 T15 AK-4014 Led Bulbs for For Chevrolet Ford GMC Honda Nissan Toyota Truck Backup Reverse Lights 45 Pcs Chipsets 45-SMD Led Light

2 Pcs T10 Led Bulb Super Bright 1000Lm 6000K Led Canbus Error Free 912 921 T10 T15 AK-4014 Led Bulbs for For Chevrolet Ford GMC Honda Nissan Toyota Truck Backup Reverse Lights 45 Pcs Chipsets 45-SMD Led Light  The Kids' Yoga Deck: 50 Poses and Games

The Kids' Yoga Deck: 50 Poses and Games  Stainless Works SSS010 Stainless Steel Beverage Dispenser Spigot (Fits 5/8 inch opening)

Stainless Works SSS010 Stainless Steel Beverage Dispenser Spigot (Fits 5/8 inch opening)  SZCO Supplies Viking Sword

SZCO Supplies Viking Sword  Wrapper - Hempwick Dispenser (colors may vary)

Wrapper - Hempwick Dispenser (colors may vary)  3M AquaPure AP431 Scale Inhibition Replacement Cartridge, Easy Change High Capacity Water Filter for AP430SS Replacement Water Filter

3M AquaPure AP431 Scale Inhibition Replacement Cartridge, Easy Change High Capacity Water Filter for AP430SS Replacement Water Filter  Star Shower Collection by BulbHead (Star Shower Tree Dazzler)

Star Shower Collection by BulbHead (Star Shower Tree Dazzler)  8 Tier Cascade Wedding Cake Stand (STYLE R800)

8 Tier Cascade Wedding Cake Stand (STYLE R800)  Ultra Pro Heavy Metal D20 2-Dice Set - Antique Bronze

Ultra Pro Heavy Metal D20 2-Dice Set - Antique Bronze  Eleven Madison Park: The Cookbook

Eleven Madison Park: The Cookbook  Cold Steel 92BKGMZ Gladius Trainer

Cold Steel 92BKGMZ Gladius Trainer  Finding Dory 10" Hank Plush

Finding Dory 10" Hank Plush